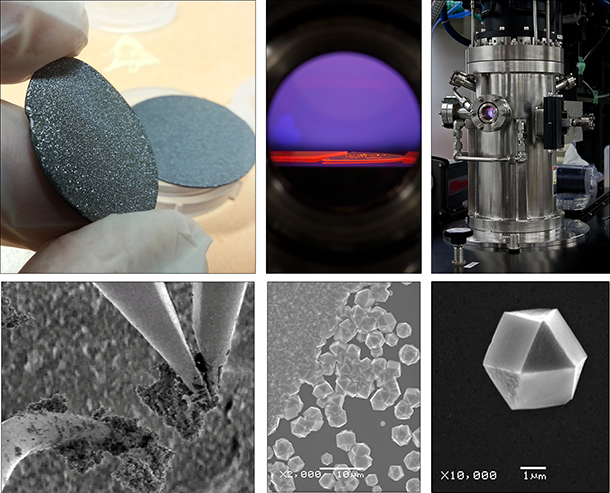

At the Diamond CVD & Nanoparticle Facilities at Macquarie University we grow diamond from a hydrocarbon gas mixture using the Chemical Vapour Deposition (CVD) method. Our expert specialists can manufacture single crystal diamond microparticles or continuous polydiamond films over large areas and on various substrates.

Diamond has many novel properties that enable a diverse range of applications. Our CVD diamond has been used for tool coatings, thermal management and in emerging optical applications of nanocrystalline diamond.

Within our Facility we also house a Field Emission Scanning Electron Microscope (FESEM) to investigate micro and nano surface structures. Our FESEM (JEOL JSM-7100F) provides topographical information at magnifications as high as 1,000,000X.

In order to allow in-situ physical handling, assembly and characterisation of samples at the microscale, our FESEM has been fitted with Kleindiek manipulator probes and grippers.

To further supplement our Facility, a bench top planetary ball mill is used for grinding sample material down to very small sizes. The interplay between frictional and impact forces within our ball mill can effectively reduce material sizes to the nanometre scale.

Services offered include:

Services offered include:

- Growing continuous polycrystalline diamond films on various substrates

- Producing monocrystalline diamond microparticles

- Creating ball-milled nanoparticles

- Field Emission SEM with nano-manipulator probes and grippers.